Even if it is a purely pressure sensitive keyboard - without velocity nor mechanical parts - I think it is really nice for some sort of sounds (warmpads, brass and solo strings).

I can set a velocity number on my R2M ribbon controller. That is not a standard function though but a code mod somebody did for me. If velocity is not present one can then at least place the velocity on a fitting level. First of all it avoids everything sounding FF all the time which also helps to keep the DAC's from whatever you use as a sound generator from overdriving. Furthermore one simply needs the MIDI headroom to make the poly aftertouch / control aspects work at all!

Basically people have been living without velocity for years and with good poly aftertouch the pressure component becomes a velocity equivalent or can even be converted into velocity data. So imagine that preset level as a sort of minimum level and everyhting hitting hard and fast enough above that level, call it immediate pressure, will work very equal to velocity.

An effect I love to use on the Yamaha CS80 is to have one channel on all the time but set the filtering of the other channel up in such in such a way that that channel only fades in when aftertocuh is applied. Just a user tip of course but also a good example of how one can think when poly expression is available.

Main conclusion: Good poly afterotuch will compensate for a lack of velocity,

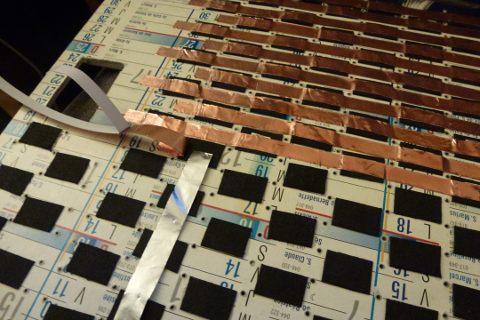

With the FSR72, the problem is that stacked octaves cause issues when playing melodies, it is not very natural to go from line to line. Thus, i think having two octaves per row would be nice.

Two octaves would actually be a bit of a minimum to get a good natural from left to right pitch perception.

I would say 96 keys on an hexagonal pattern

My bad joke basically menatto implie that one would replace every note on a full size piano keyboard by at least 2 keys per note. An original Janko actually has 3 keys per note but that might be overkill anyway

I'd say: go for a prctivcal number (and then 96 is already quite high) and simply make the ends of the boards in such a way that using more then one beside the other will be reasoably practical. Just like Roli now offers 2 octave units that can be used in a modular fashion. If one then really wants a bigger size version (say 6 octaves) and has the balls to kleep building it at least is still an option.

stacked octaves à la Janko (5 octaves):

3:01 3:03 3:05 3:07 3:09 3:11 4:01 4:03 4:05 4:07 4:09 4:11

3:00 3:02 3:04 3:06 3:08 3:10 4:00 4:02 4:04 4:06 4:08 4:10

2:01 2:03 2:05 2:07 2:09 2:11 3:01 3:03 3:05 3:07 3:09 3:11

2:00 2:02 2:04 2:06 2:08 2:10 3:00 3:02 3:04 3:06 3:08 3:10

1:01 1:03 1:05 1:07 1:09 1:11 2:01 2:03 2:05 2:07 2:09 2:11

1:00 1:02 1:04 1:06 1:08 1:10 2:00 2:02 2:04 2:06 2:08 2:10

0:01 0:03 0:05 0:07 0:09 0:11 1:01 1:03 1:05 1:07 1:09 1:11

0:00 0:02 0:04 0:06 0:08 0:10 1:00 1:02 1:04 1:06 1:08 1:10

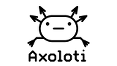

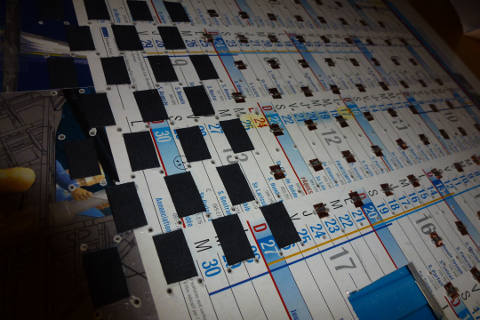

First of all a question: What is the system in the numbering you use in these examples? Per 2 rows it all makes sense but I see no Jnako style repetition of the same numbers in the other row combos. As you can see with my convertors I have decided on 4 rows on top of each other. Having 2 keys per note and the offset is allready very errgonomic. So if I understand you correctly my Janko solution woudl be coded:

0:01 0:03 0:05 0:07 0:09 0:11 1:01 1:03 1:05 1:07 1:09 1:11

0:00 0:02 0:04 0:06 0:08 0:10 1:00 1:02 1:04 1:06 1:08 1:10

0:01 0:03 0:05 0:07 0:09 0:11 1:01 1:03 1:05 1:07 1:09 1:11

0:00 0:02 0:04 0:06 0:08 0:10 1:00 1:02 1:04 1:06 1:08 1:10

and the other notes then to the right of that in a similar fashion.

(Oops, why does this copy not repeat the row offsets? I Hope you get the idea anyway!)

My goal is to keep it compact (30x20 cm or so). That's why i stack octaves.

If you prefer a wider format, i think it is quite possible.

Ah yes. now I get it. Then I would actually like to further focus my earlier remark. Make the standard layout 4 rows high, 2 octaves wide. So basiclly half the height of what you propose above. One can then decide where to place the other octaves by combining more then one pad. Again: Make it modualr so to speak. In my minds eye I now suddenly see jigsaw puzzle type lugs in the rubber to connect evrything up, ha ha.

I think that a 12 x 16 = 192 key keyboard is still doable (scan freq=3000/16 = 187 times/s using 74HC4067 mux,16 2N7000 and 192 1N4148)... but that's a lot of work.

Sounds fine. As long as the latency stays within a few milliseconds it should actually still outdo DIN MIDI anyway

Let me know what you think of the modular idea.