I've used a VHS case to house my Zoom 1201. They are quite useful!

Anyone planning to make and sell an enclosure?

Did you ever sort this? Afraid I dont understand the laser cutting file types either.

UK here too.

Richard

@Zedkah @chriss , I had my enclosures cut at razorlabs uk based on @janvantomme files.

I made two changes

a) increased the size of the slots on top/bottom to allow for 3mm acrylic.

b) put them on to a larger template, as I had 5 cases made at the same time, so optimised the placement on the material to fit.

I think I used inkscape from memory... and I don't think I changed the colours or line thicknesses, though I did review them all, so perhaps I did... the template you download from them, gives the specifics about colours/thicknesses, and its easy to select them in the SVG.

(I think you need to do an ungroup if i remember correctly)

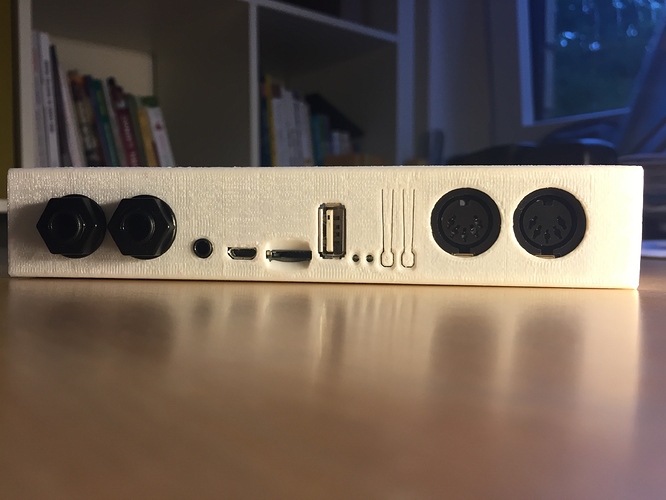

p.s. I used a mixture of plywood and acrylic, and was very pleased with the results.

you can see them here

I possibly can dig out the templates, but possibly not much use to you as parts are split over 3 different sheets, to get the most out of each.

I had a play with this and have copied the SVG files across to the razor labs templates. I then discovered that the scaling was wrong. the box seems to measure 14 cms across where as the axoloti is 16 cms long ! Any pointers here? I dont like the idea of draging to re sizing the objects until some test measurement looks right.

Not used inkscape before so I obviously need to put some more time into getting what it is doing. Id like to design a slightly bigger box with some headroom for some pots in the top but the back panel with the holes and slots needs to be dead on.

Any updates on this most needed piece? ..I'm so eaderly waiting for a 3D printed enclosure for the Axoloti v1. ...THX!!!

For those wanting a pre-made solution, I can recommend the PacTec PT series.

The larger PT-10 is the enclosure used for the original Adafruit X0xB0x

The PT-8 may also be big enough for an Axoloti. It's been used by MFB, for example for their MFB 522 Drum Machine.

They're quite pricey, but they have the advantage that the top and rear panels can be removed for easy drilling, painting, labelling etc. You can even send them to Schaefer/FPE for milling and engraving, if you're feeling rich.

a|x

aton, the file you supplied is still corrupt or incomplete. can you please upload it again

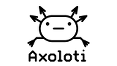

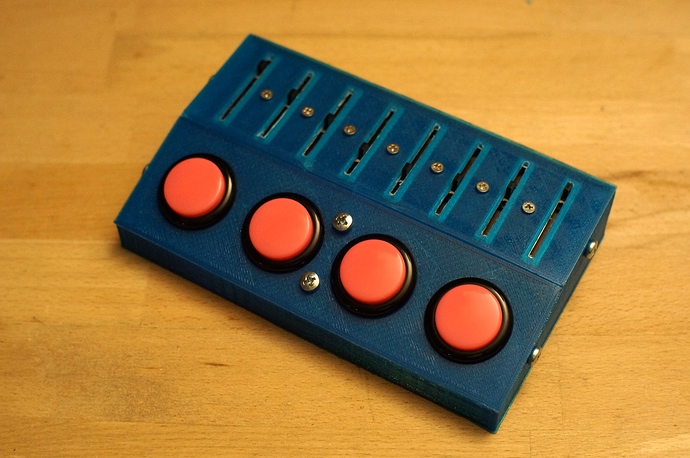

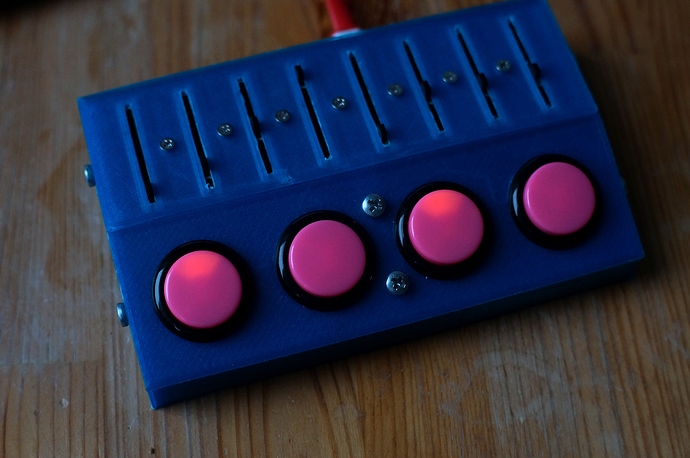

Hi everybody, this is my first post on this forum, just to share my 3d-printable enclosure design with this awesome community here:

It's made with OpenScad and is therefore quite easy to customize (althougt the code lacks comments and needs refactoring). The front plate (where the connectors are) is derived from Jens Groh’s design.

https://github.com/fpiesik/AxoStomp

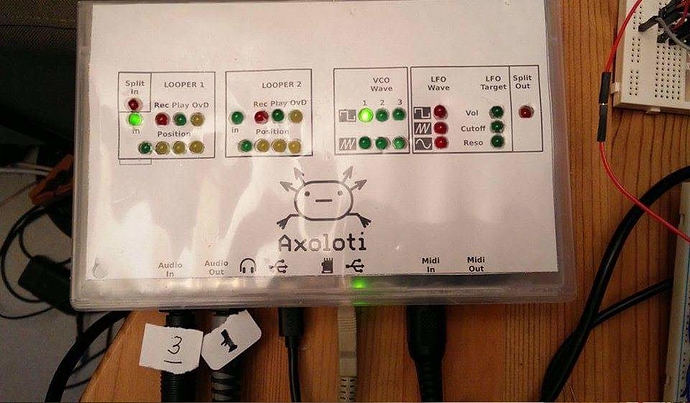

This looks incredibly dope!

I'm in the middle of a stompbox project using behringer fs 2 footswitches, that is quite similar to your layout. Feeling almost tempted to go for your enclosure but I guess it makes more sense to finish my project now

Personally I would add led next to the buttons for visual feedback but great thing really!

Love the angled frontplate. I've mused plenty over how to do that with acrylic but just can't work it out.

yea, I had to remember some math lessons from twenty years ago and use Pythagoras theorem to calc that top plate