Where is the mechanical failure point? The 4 solder "stubs" that go in a hole? Those are (mostly) serving mechanical attachment. Resoldering these, it's a bit complicated. In manufacturing, these are (reflow) soldered on the top side like surface mount components. And later, they're soldered a seconds time from the bottom side using wave soldering. Unfortunately this appears to trap a bubble of air in the hole so the second soldering does probably not reinforce the top side solder.

If you attempt to solder the 4 stubs from the bottom, I think you should first try to wick away the bottom solder to open the cover to the trapped air bubble (using desoldering braid). And then apply solder from the bottom side again. I would warn against adding solder to the front 2 stubs from the top side, excess solder will creep into the connector making it impossible to insert a plug.

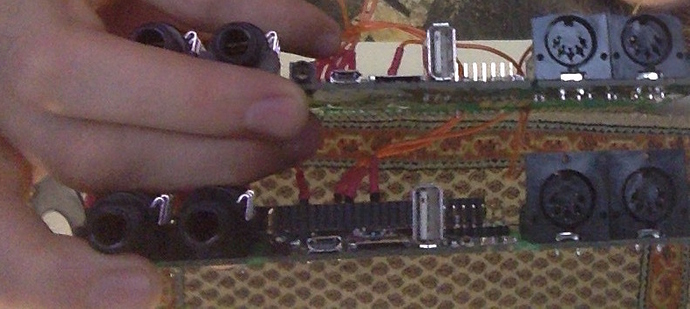

On your picture, it looks like the usb socket is bent, it is board on the bottom that is failing, right?

Essentially even if the 4 stubs are loose, this would not affect the connection, as they do not carry a signal. So it could be the signal connection inside the socket that is failing, or the (5) surface-mount solder joints at the rear side of the socket that connects the usb signals from the connector to the circuit board.

If the socket is deformed, it needs to be replaced. Replacing this (Hirose ZX62D-B-5P8) can only be done using hot-air soldering tools, perhaps find someone locally that has hot-air soldering tools and knows how to use them. Replacing the socket with a classical soldering iron is impossible.

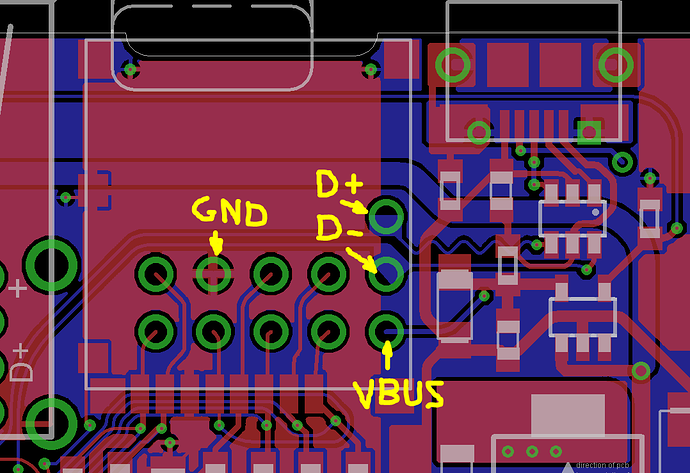

One alternative (since board revision 1.1) there are solder pads reachable on the bottom side that contain the usb device signals, you could connect a female "B" type usb socket, or connect a male "A" cable. The following picture shows the signals on a top side view (but you can only reach them on the bottom side).

From a design and manufactoring perspective, I believe I have done what I could do to make the micro-usb connector as strong as possible, and many other products could break similarly. Avoid stress on the micro-usb cable when plugged in, unplug before packing/transport. I did some destructive testing on the micro-usb socket long time ago, plugging a cable and then bending the plug until it breaks, and I observed that the cable plug would break before the socket. Still, stronger cables than the ones I used in testing will cause the socket to fail.