What would you consider a 'higher quality printer'? ... and does something like the Ultimaker2 use 0.4mm nozzle?

3dhub does tell you which printer the hubs using. so can look for something suitable (and I can explicitly check with the hub too)

my fear, is that its not just the printer though... is it possible that the hub doesn't have the printer setup in an optimal way, or calibration is not as tight as it needs to be? this would be hard for me to know in advance.

of course, outsourcing (so lack of control) and my lack of knowledge also plays a part in all of this

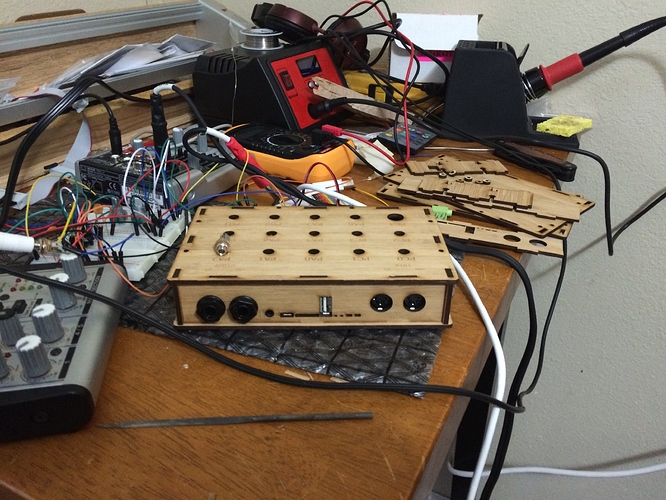

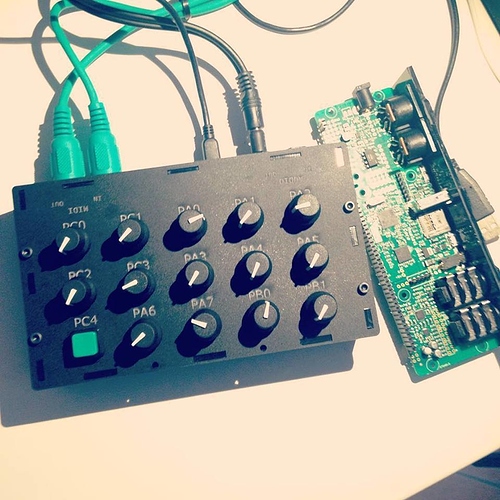

deformation, it didnt seem warped... more like things were a few mills out... e.g. if inserted the front over the audio jacks, then the usb host port was about a 1mm out, and the midi ports about 2mm off ... almost like the thing had perhaps 'shrunk'. also I noticed the 'indentations' front side of the faceplate were not well formed.

yeah, I think a lower precision design would be possible, in particular the sidewalls would have to be quite a bit thicker. or perhaps have side walls separate, so it becomes a 6 part structure.

and the audio outputs could be much bigger (to allow for tolerance) since they are 'covered' by the screw on cap. possibly other outlets could be slightly larger too, not as tidy, but more room for manoeuvre.

Im not quite sure, how the latches should work, if they are too fine they would be problematic, perhaps a bulkier sliding system might work...

(probably generally means the case would be a bit bulkier, but thats not an issue)

Id actually quite like a sliding lid, and a way to get the board out a little easier.. useful if you want to connect io pins etc.

I will have a think, though a bit tricky, as I don't have a printer to test designs on or iterate prototypes...

)

)