nice one mate, very cool idea.

Anyone planning to make and sell an enclosure?

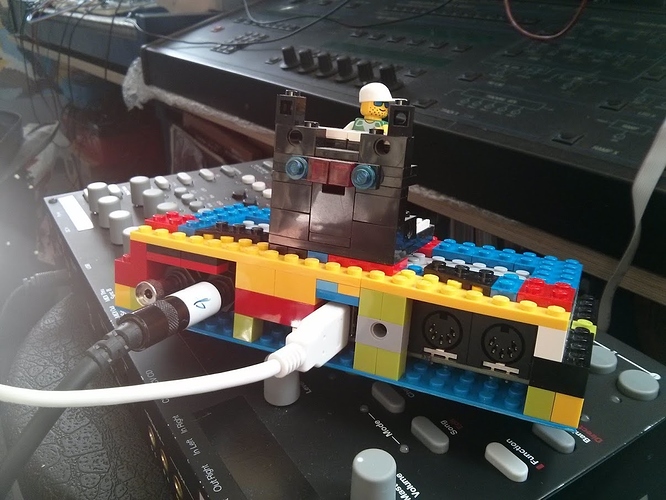

Thank you @janvantomme for your case design! My local fablab had additional requirements for etching which I was too lazy to implement, but as I chose clear acrylic we can still see our little friend on the bottom.

For people who are hand building their cases, I've put together a set of panel templates based on the files janvantomme posted earlier. I've put some basic instructions in the PDF itself, but it should be pretty obvious how it's meant to be used.

The outer border shows the minimum INNER dimensions the front and side panels have to be to give you enough room (almost identical to the original file).

I added:

-a guide showing the bottom plane of the PCB (not including solder points) for figuring out where to position it if you use standoffs instead of mounting to the panel itself.

-center marks for all of the round holes in the front panel, for drilling pilot holes. With a steady hand and the right size bits you should be able to drill out the holes for the audio, midi and headphone jacks without any filing needed.

-a mirrored template for using on the inside faces of the panels, since I can imagine designs where that would make aligning the template easier.

I haven't actually made an enclosure with this yet but I did print it, cut it out and check the alignment of the two halves against my axoloti and it looks like everything lines up as long as the inside faces of the panels you cut meet where the line marked A on the template is.

Axoloti front panel and DC input templates

Hope this is useful!

(still to do - measure and add drill guides for the panel-mount holes on the MIDI DIN jacks)

I'm currently working on an enclosure that can then be 3d printed. Currently I have the front plate right, now I just have to do the sides, and bottom for the mounting holes.

I think I'll get 2 of these and drill some holes myself.

Not sure how to cover the back, but that is probably the easiest part.

Please organize a group buy (or another indiegogo project) for the enclosure. Really necessary for everybody who doesn't have a fablab in their neighborhood. Or just easy to all have the same case.

how much do you want to spend?

personally I don't really like the design of these lasercut boxes, but I would prefer a small metal box (like a nanoverb).

But also, something to think about is how to open the box to add cables and such; should it be open at the back side and accessible, or fully closed? should there be space to add some extra knobs? etcetc.. lots of variations possible, and I guess that makes it difficult to come up with a good design.

Indeed lots of variations possible, hard to design a one-fits-all solution. I'm also not a huge fan of lasercut acrylic, or extrusion-based 3d printing.

I'm thinking of designing waterjet cut sheet metal parts that can be shipped flat, bent manually (with cuts to make bending easy), and assembled with self-tapping screws, decorated with stickers, to keep it economical.

Powder-coat paint, silkscreened, pre-bent enclosures would get expensive.

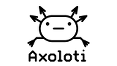

I'm going to be building a MidiREX in a couple weeks, I might have to borrow that Lego idea for it.

The other week I built the posted enclosure at the local makerspace.

The midi-connectors are a little too snug (stick out about 0.5mm) so I couldn't mount the board directly above the holes. In my case the mounting-screws had to be a little skewed to fit everything, but at least now I can just stuff it in my bag without worrying.

Next version I'll try to come up with something more custom to my needs (now I can hardly access the gpio for instance).

One big downside of acrylic cases is of course that they can build up static electricity. Hardly the best environment for sensitive electronics :o

I've been searching for a company that makes custom cutouts for metal panels, but not easy to find.

I've found a company in the US that can do it relatively cheap, but shipping costs make it expensive again. So I'm looking for a local company now, but could take some time (have other stuff to do too

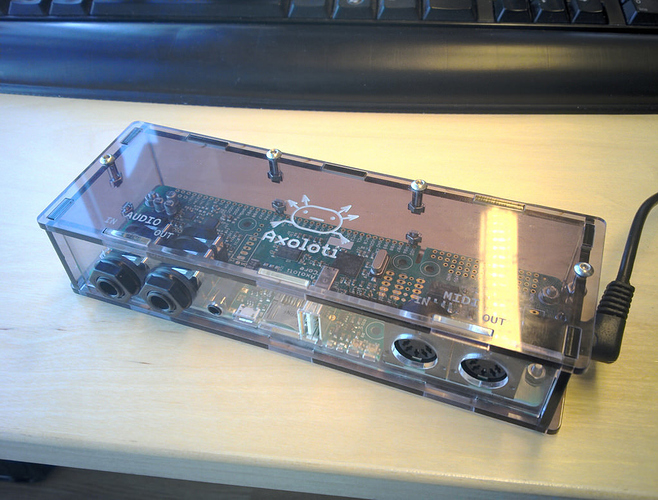

Bass guitar fx stompbox I posted in other category,

4 pots, 5 color led's, two switches, one push(/stomp)button, EV-5 expression pedal connector

I noticed the MIDI DIN holes were a bit too small when I was using a printout for cutting my temporary panel. They're sized to just fit the bare DIN plug but their diameter should really be maybe 3-4mm to accomodate the molded plugs that are common on shorter MIDI cables. Even the nicer metal plugs have a bit of taper and are probably a tight fit, although I didn't try one before I filed the holes bigger.

another pedal, this time with midi/dc power section cut off to fit in small package

EDIT: by cut off, I mean split from the main pcb and reconnected of course...(the MIDI ports are on the front side)

anyone know this website?

http://collectivecases.com/index.html

maybe will be usefull for the axo case