Thank for your answers,

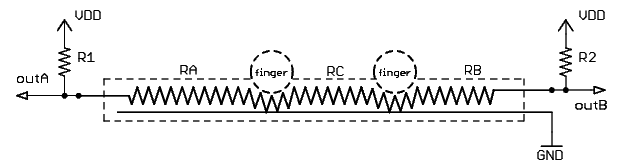

I have made some trials some time ago with Arduino using only one resistor this way http://www.eerkmans.nl/wp-content/uploads/2014/03/meter_resist.png.

The result was that you get "0" when you dont touch the ribbon. If I dont use the resistor it generate unstable numbers.

Using the "better multi touch version" what will be the behaviour? I am waiting for my Axoloti board so I cannot make trials by myself now.

I have reading the article and it is great although I don´t understand the electronic working completely. I have only basic knowledges about and it is not too clear for me. Can you shed some light...?

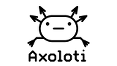

Attending to the practical installation How do I have to connect everything?:

Ribbon has three pins, so:

Ribbon GND --------> Axoloti GND

Pin A ----------------> resistor (100k?) -------> ????

Pin B ----------------> resistor (100k?) -------> ????

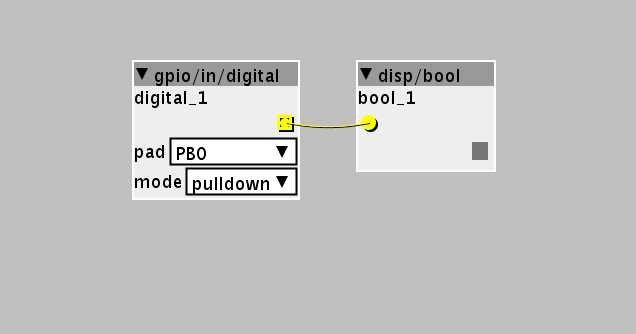

and then the maths inside Axoloti patcher.

Another questions:

- What volts conection I have to use, 3.3v or 5v?

- Do you have some experience about what ressitences values is better to use?

Thanks janvantomme about using Sharp GP2Y0A60SZ too. Yes, it probably works but according the article it is not best way.